In-Cirquit Test

Parametric evaluation oh the board

Component polarity

Verification

Characterization

Impedence calues of the circuit

TECHNOLOGICAL EXCELLENCE

PreventLab is equipped with two flying probe machines for conducting electrical tests.

SPEA 4080

Model 4080 with 8 probes allows contacting pads of size 40-50um, ideal for testing miniaturized products or HDI.

In addition, it is possible to control the impact speed (soft-touch) and the probe weight to avoid damaging particularly delicate substrates or finishes (silicon wafers, ENIG finishes, flex circuits).

Additional tests:

Junction scan

Detects the presence of protection diodes in integrated circuits, thereby verifying the successful soldering of the pin.

Displays dimensions

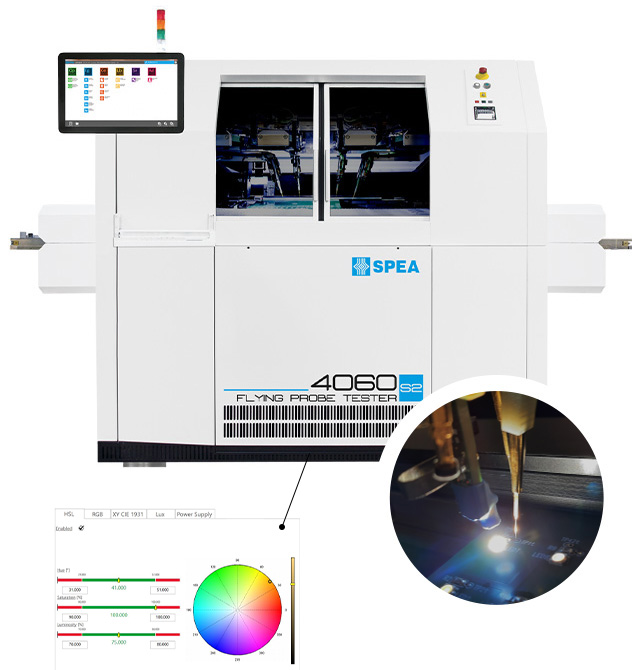

SPEA 4060 S2

Model 4060 series 2, a 6-probe system ideal for small and medium productions.

The use of LEONARDO OS2 software enables this machine to be compatible with SPEA 4020 and SPEA 4050 systems.

Additional tests:

Junction scan

Detects the successful soldering of component pins and verifies the presence of diodes where applicable.

Electro Scan

Detects the open status of integrated component pins by measuring the electric field induced by a stimulus and detected by a dedicated tool.

Light Meter

A sensor characterizes luminous parameters, color, and light intensity of the LEDs on the board.

Displays dimensions

START NOW!

Fill out the form and you will be contacted for any information and quotation related to the service.

WE CREATE THE TEST PROGRAM!

Provide the following files necessary for the creation of a test program for the electrical test, and we will proceed with the creation of the test program to be used.

PCB design in ODB++ format

Bill of Materials (BOM) in Excel or CSV format

Schematic in PDF

FAQ - E-TEST

A good electrical test drastically reduces costs associated with field returns, significantly increasing product reliability.

Yes, there is a dedicated tool for programming on the integrated circuit.

Yes, although Test Points are preferable, it is possible to use the pads of unmounted and mounted components.

Yes, regardless of the type of mounting, a test program is generated, which may use the PTH pin pads as contact points if there are no alternatives.

Yes, even in the absence of edge strips or protruding components, we use an RLS (board support) that adapts to the irregular shape of the boards.

Yes, the machines are located in a certified EPA area and are equipped with a connection point to the reference ground.

Yes, in this case, continuity or the presence of short circuits between the various traces is checked where not provided.

The creation of a needle bed tester limits its use to a single product, which incurs a high cost for small production that is not amortized.