Control

assembly proces

Qualification

solder paste

Prevention

failures

OUR OFFER

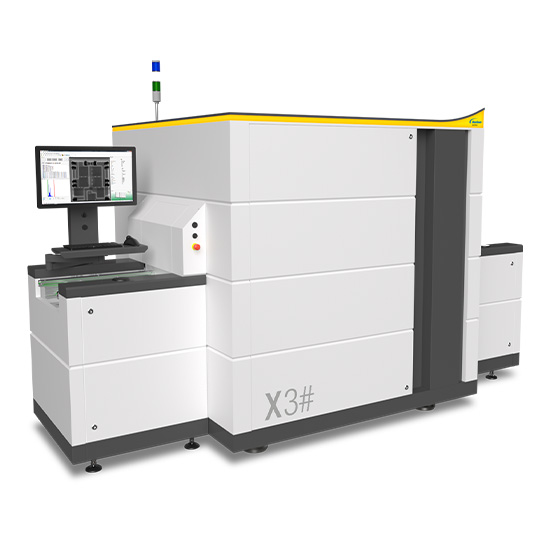

PreventLab is equipped with top-of-the-line equipment from Nordson Dage.

NORDSON X3#

MatriX X3# is an automated inspection system designed for sophisticated high-speed inspections in SMT production.

Teconologies:

Slice-Filter-Technique (SFT)

Patented X-ray technology.

Off-Axis e 3D SART

They represent a reliable solution for inline inspection of double-sided PCB assemblies.

The mobile detector's axes allow for high-speed off-axis image acquisition from various angles and directions with maximum image quality and resolution.

QUADRA 7

The machine has a resolution of 0.1 µm/pixel and allows for acquisitions in four different modes:

START NOW!

Fill out the form and you will be contacted for any information and quotation related to the service.

Examples

FAQ - X-RAY ANALISYS

Yes, X-rays allow access to the internal structure of components, such as the junction of a diode, the metal frame of a die, or the wire bonding of an integrated circuit.

Yes, to check the integrity of the traces (open/short) and the copper planes, provided that the PCB layout and the overlapping conductors allow for it.

Generally, it is not; only in the case of large samples undergoing tomography is there a dimensional constraint for the sample holder of 4x8 cm. However, in these cases, the situation can be resolved through laminography, which still provides a 3D reconstruction, albeit with less detail, but is often still capable of identifying the issue.

Yes, the maximum allowed weight is 5 kg.

It's not always possible to detect such small distances, but the machine allows for the detector's tilt angle to be changed up to 270° to enable analysis from different angles. If I can't clearly identify a defect, I can still locate a suspicious area to analyze using more detailed techniques (such as a micro-section).

The machine allows for adjustments in working voltages and currents, enabling the analysis of non-metallic materials as well.