Incoming

inspections

Qualification

processes

Prevention

Failure Analysis

OUR OFFERA

A comprehensive service to verify the cleanliness level of the production process

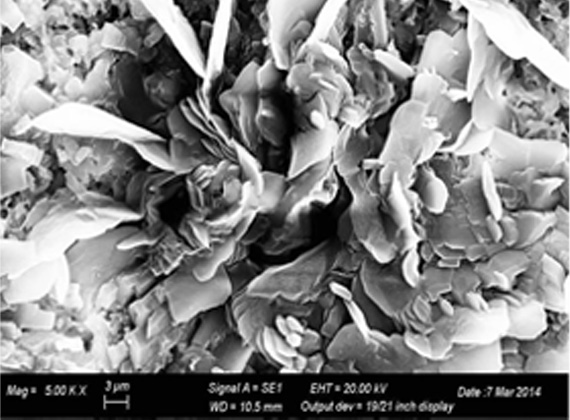

IC - Ion Chromatography

We perform IC (Ion Chromatography) tests according to the reference standard during the qualification phase of the PCB/PCBA production line and the chemicals to be used (solder pastes, fluxes, manual soldering wires).

The IC test is used to identify the presence/level of anions that contribute to total ionic contamination. The ion chromatograph can accurately measure ion concentrations down to 0.05 parts per million (ppm), detecting the chemical composition of the following seven anions:

- Chlorides

- Bromides

- Fluorides

- Nitrites

- Phosphates

- Sulfates

- Nitrates

Reference standard

- IPC-TM-650 2.3.28

TIC - Total Ionic Contamination

We are able to ensure the maintenance of production capacity and the assembly process concerning cleanliness.

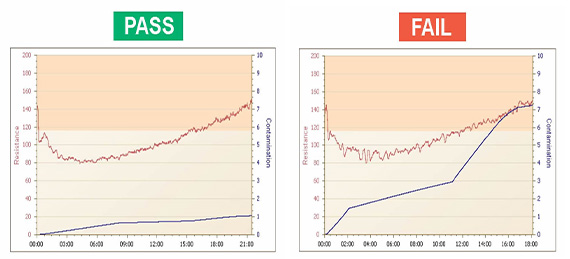

Ionic contaminants present on the sample are washed away in a solution of 75% isopropanol / 25% H2O, thus altering the electrical conductivity.

The obtained value indicates the cleanliness level expressed as Sodium Chloride (NaCl) equivalent, represented on a graph that shows a verification curve.

The instrument automatically takes conductivity readings, converting them into contaminant quantities. In case of a failure, it is advisable to perform this test periodically to maintain target values in production processes and conduct an Ion Chromatography test.

Reference standard/h2>

- IPC-TM-650 2.3.25

PreventLab is equipped with Aqueous ZeroIon equipment for rapid verification of contamination levels..